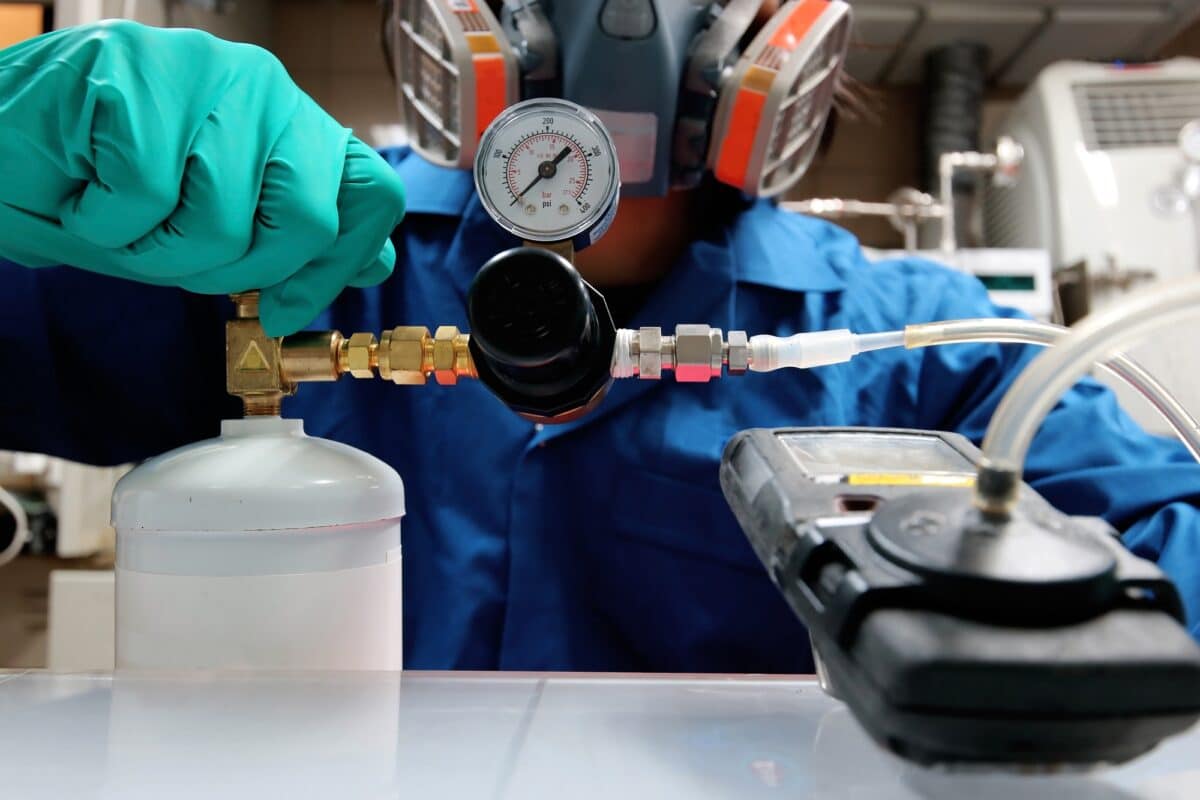

Gas detector calibration is a critical service that ensures gas detection devices function accurately in detecting hazardous gases such as CO2, O2, H2S, and more. Regular calibration is essential to avoid false readings, which could lead to life-threatening situations in environments like industrial plants, offshore platforms, or confined spaces. Gas detectors, over time, may lose accuracy due to sensor drift, exposure to harsh elements, or regular use. Calibration adjusts the sensor’s response to match a recognized standard, ensuring that they perform reliably when needed most.

Without proper and regular calibration, gas detection systems may fail to provide adequate protection, exposing workers to dangerous gases and non-compliance with industry safety regulations.